For use with L-CO2 Dewars, bulk systems, or high-pressure siphon tanks.

29-30009-03 Three ft.

29-30009-06 Six ft.

29-30009-12 Twelve ft.

For use with Dewars or bulk systems. Comes with a Pressure Relief Valve for added safety.

29-30019-03 Three ft.

29-30019-06 Six ft.

29-30019-12 Twelve ft

1/2 SAE Out See Below List

29-30024-03 Three ft.

24-0006 Six ft.

24-0007 Twelve ft.

For use with Dewars or bulk systems. Comes with foam insulation & a Pressure Relief Valve for added safety.

29-30029-03 Three ft.

29-30029-06 Six ft.

29-30029-12 Twelve ft.

29-30034-03 Three ft.

29-30034-06 Six ft.

29-30034-12 Twelve ft.

For use with all models and standard temperature Ranges, -100°C to +200°C (-148°F to 392°F) 29-30044-00 SD288 requires our 3/4 Inch hose. Use the -00 to indicate length, for example 29-30039-12 for twelve feet.

Liquid Nitrogen Hoses that have a Safety PRV (Pressure Relief Valve) Port. Points the PRV downward so moisture doesn’t accumulate in the valve, prevents possible freezing. An added benefit is the pressure when relieved points downward.

Greatly reduces the noise level and dampens the pitch of coolant being spent by a Thermal Platform Larger Thermal Platforms SD288 and above use 24-00010.

For use with cryogenic Dewars. Greatly reduces the sound of the tank venting built-up pressure.

Connect two Liquid Nitrogen Hoses to a single source.

Connect two L-CO2 hoses to a single source.

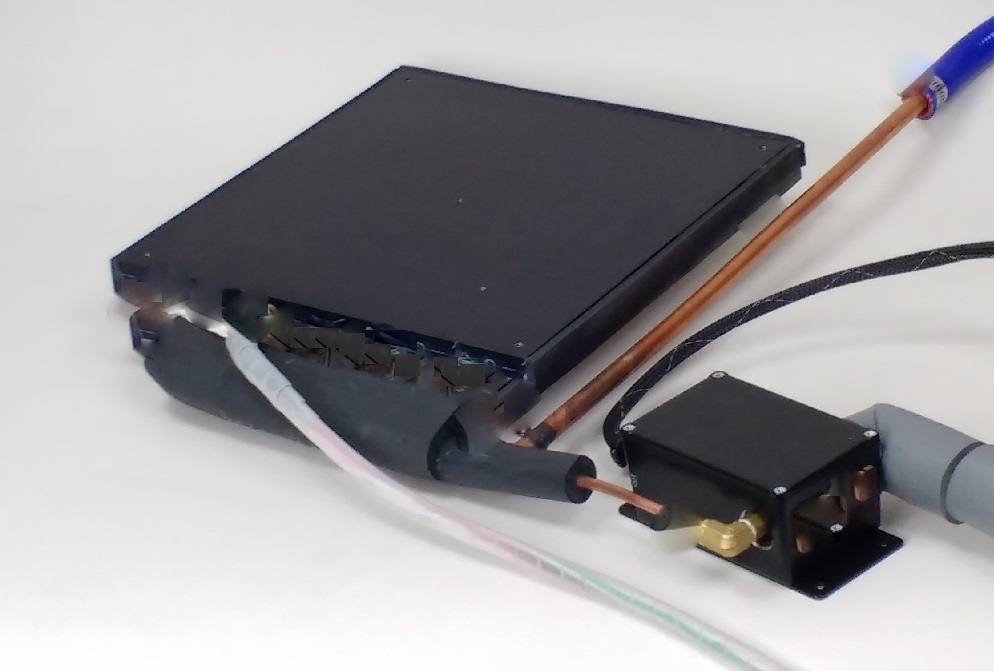

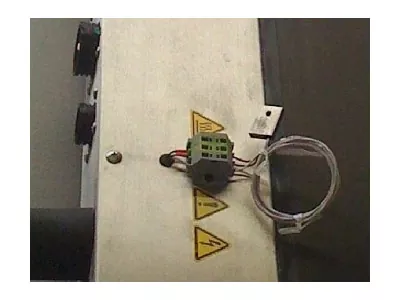

Used when a platform is to be oriented in odd positions or installed inside a chamber. All cryogenic valves are sensitive to orientation. The remote valve box prevents this type of failure from occurring. Please specify the required AC Voltage. 12=120v, 28=208v and 24=240v. Example 29-30079-12 would be 120 VAC.

29-30079 Single Remote Valve, 1/4 Flare Input

29-30084 Single Remote Redundant Valve, 1/4 Flare

29-30089 Single Remote Valve, 1/2 Flare

29-30094 Single Remote Redundant Valve 1/2

Used when platforms need to be oriented in odd positions. All cryogenic valves are sensitive to orientation. The remote valve box prevents this type of failure from occurring.

Please specify the required AC Voltage. 12=120v, 28=208v and 24=240v.

Example 29-30079-12 would be 120 VAC.

29-30099 Dual Remote Valve, 1/4 Flare Input

29-30104 Dual Remote Redundant Valve, 1/4 Flare

29-30109 Dual Remote Valve, 1/2 Flare

29-30114 Dual Remote Redundant Valve 1/2 Flare

Shock valves and ASCO are also available.

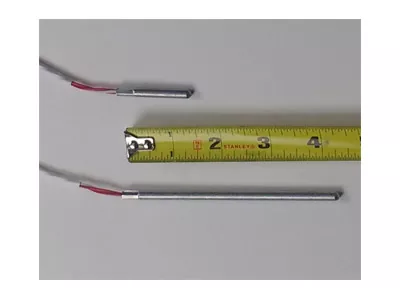

Two standard sizes of tubular probes with Aluminum Sheath, 0.188 Inch Diameter.

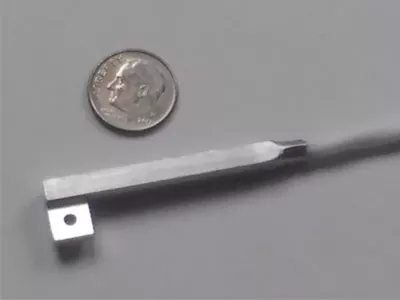

Very low mass sensor with a 0.1 Inch Diameter hole for securing to a device under test. Comes with 48 Inch lead wire

Rugged flag style sensor with a 0.1 Inch Diameter hole for securing a device under test. 28-00067 Initially designed to fit large 500Ω RTD.

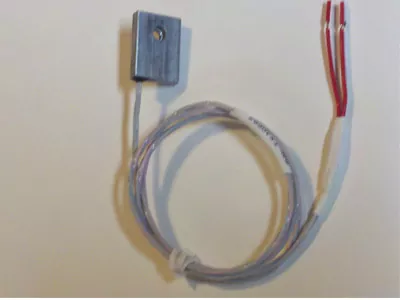

No. 4 socket head cap screw counter-bored mounting through-hole for securing to a device under test.

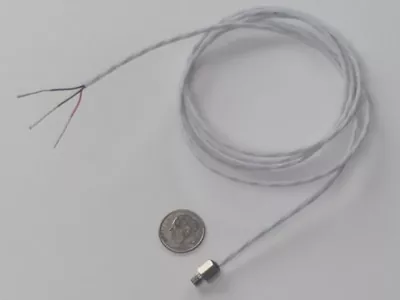

No. 8-32 threaded stud for securing to a device under test. Many available stud sizes.

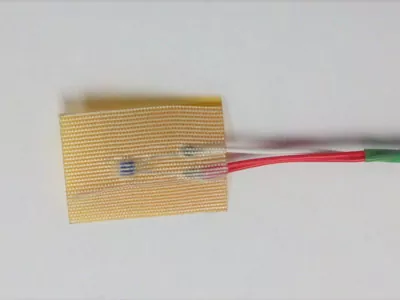

Very thin low mass Kapton Tape Sensor is available as a thermocouple or a 2 wire RTD.

No. 4 socket head cap screw counter-bored mounting through-hole for securing to a device under test.

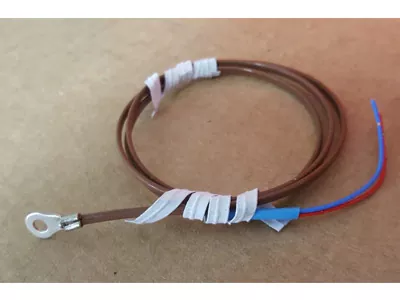

No. 6 screw lug is used for securing to a device under test. Over all wire length varies per order. Connector sold separately

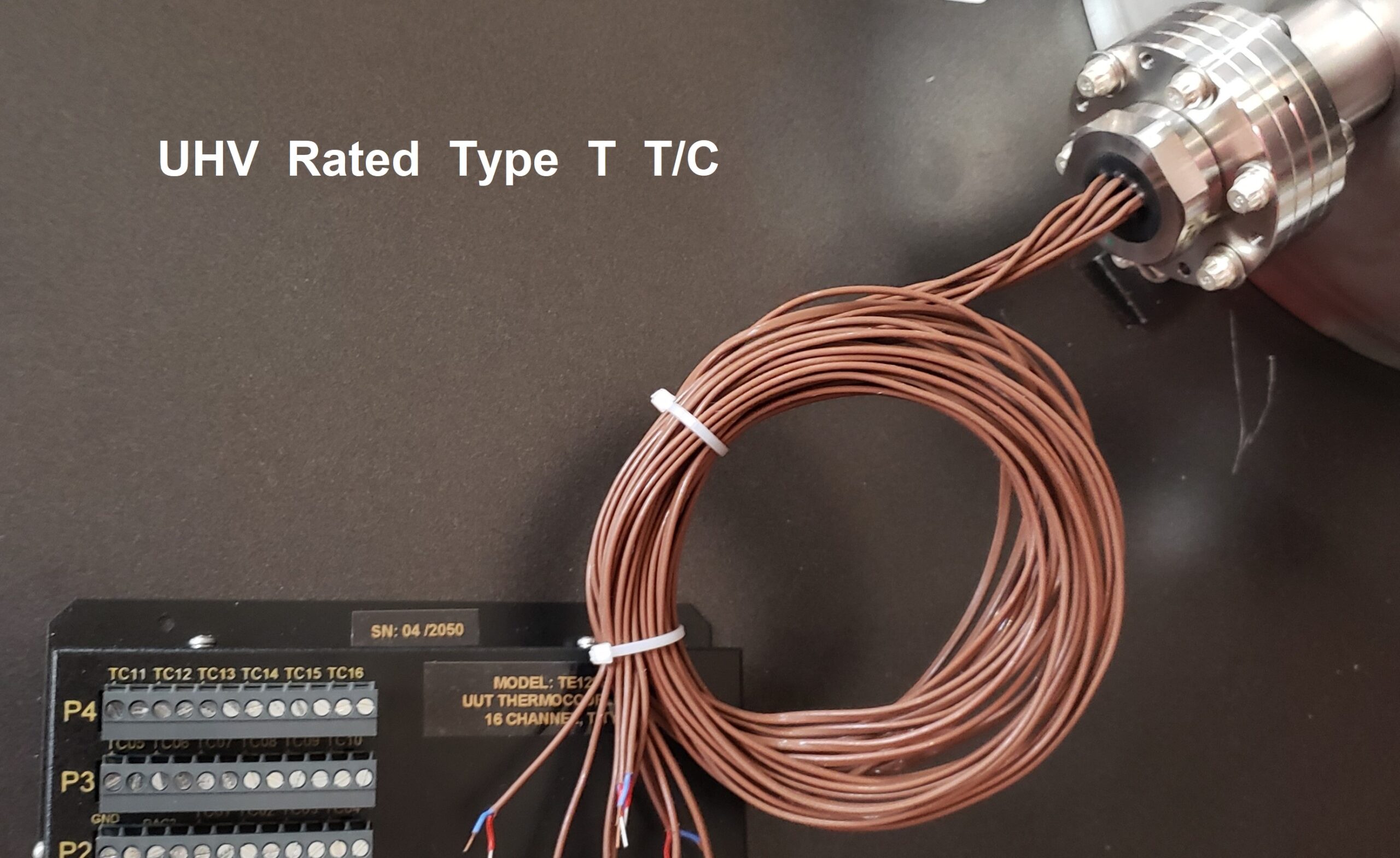

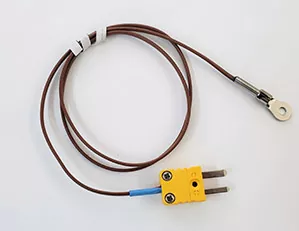

Shown here is a Type T in-line connector, part of the controller umbilical, and is available for all types of RTDs and Thermocouples.

Screw-down terminations allow the controller to be removed without removing the external sensor.

Press locking terminations in the back to keep the lid area clear for the large unit under test or HDC (Heavy Duty Clamp).

Top mounted press locking terminations for convenient connection to an external sensor.

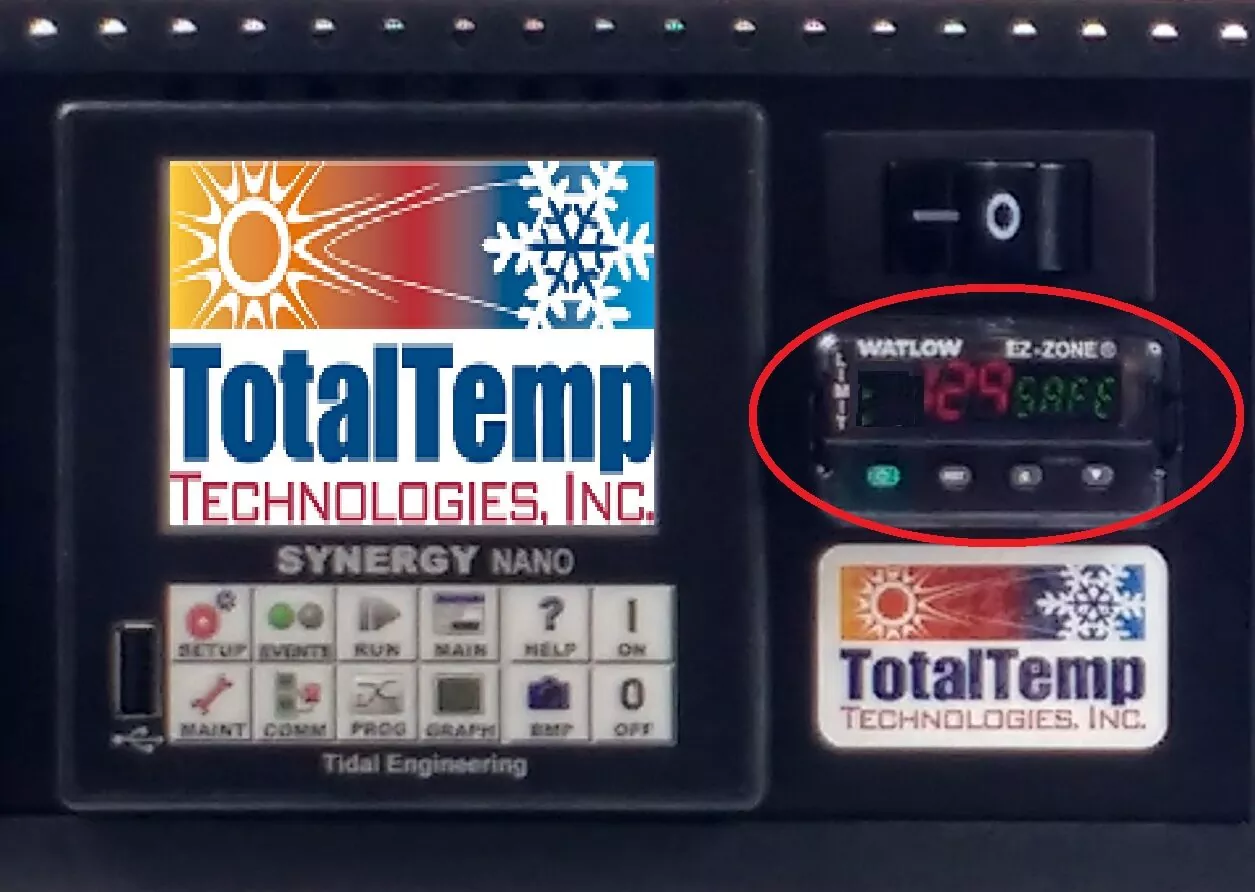

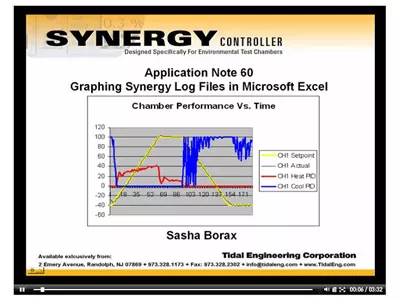

Uses Thermocouples, daisy chain up to four of these 16-Channel monitors together and acquire 64 temperatures on the Unit-Under-Test. The TotalTemp Technologies Synergy Nano Temperature Controller displays and logs these readings to the internal log file for analysis, graphing, and reporting.

Type K Thermocouple with #6 screw lug, electrically isolated as required for compatibility with Synergy Nano, 24″ Teflon lead wire, Yellow male Mini TC in-line connector included.

Type T Thermocouple with #6 screw lug, electrically isolated as required for compatibility with Synergy Nano, 24″ Teflon lead wire, Blue male Mini TC in-line connector included.

240002A With two Controllers, includes two 6 ft Umbilicals for connection to equipment.

240002B 2 Bay with one Controller, includes 6 ft Umbilical Requires 16-00041 blank panel

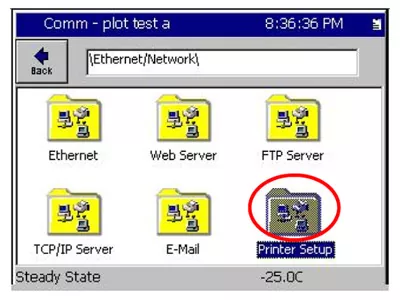

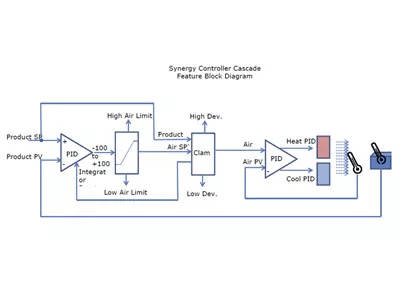

See Application Notes for further details of this Synergy Nano powerful feature.

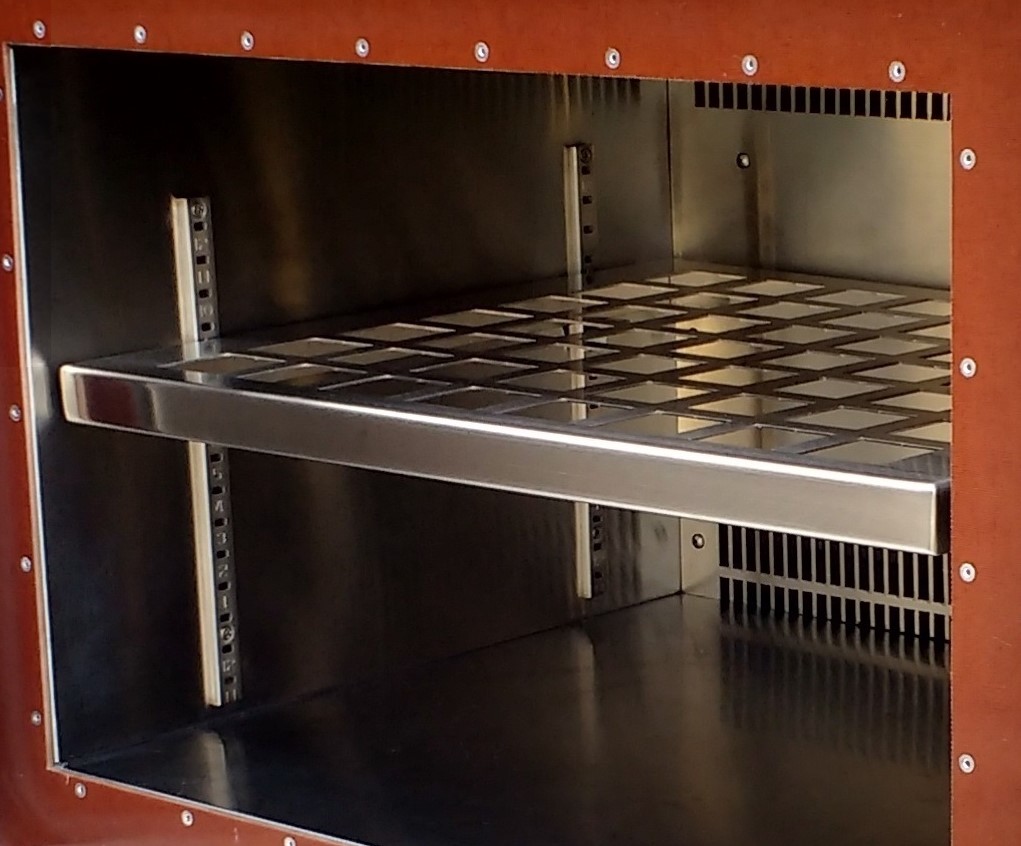

Shown on an SC144 mechanically cooled Thermal Platform with a standard hinged lid, modified internal dimensions to accommodate heavy-duty clamp.

Flowmeter comes with a press lock fitting and 12 feet of tubing. For use with gas sources with regulated pressure.

Panel Mount Flow Meter

Flowmeter can be panel mounted. Installed in 19″ rack, benchtop controller, or on purge cover.

Protect cryogenic equipment from corrosion with a chassis purge inlet. Prolonged contact with water can damage the plumbing and cause the valve coil to fail prematurely

Purging the chassis keeps condensation and frost from accumulating. For use with Nitrogen (G-N2) or dry air. Regulated pressures under 100 PSI.